The use and interpretation of piezometers is of critical importance to the monitoring and understanding of tailings facilities. This is because pore pressure has a direct impact on effective stress. The following two stories are presented to help illustrate why this is important. The two stories pertain to a series of site investigations that took place in about 1987, at a time when I was a newly minted mining engineer. Ten years later I earned a master’s degree in geotechnical engineering, and this sort of lesson became “old hat” to me.

At the first of the two sites, drilling, sampling and in situ testing (including CPTu probing) had just been completed. I had a sizable amount of metal water pipe and several isolated-tip drive-point piezometers with me. Because I was not yet a geotechnical engineer, I had no real appreciation for this equipment. I contacted my supervisor to get instructions on what to do with the piezometers and water pipe. He told me to have the drill rig press them into the tailings, each at a different depth, but all in close proximity to one-another. I didn’t realize the value of this, as I said, I was not yet a geotechnical engineer. I was certain that this was just a waste of time, equipment and the mine owner’s money. I was wrong. So wrong.

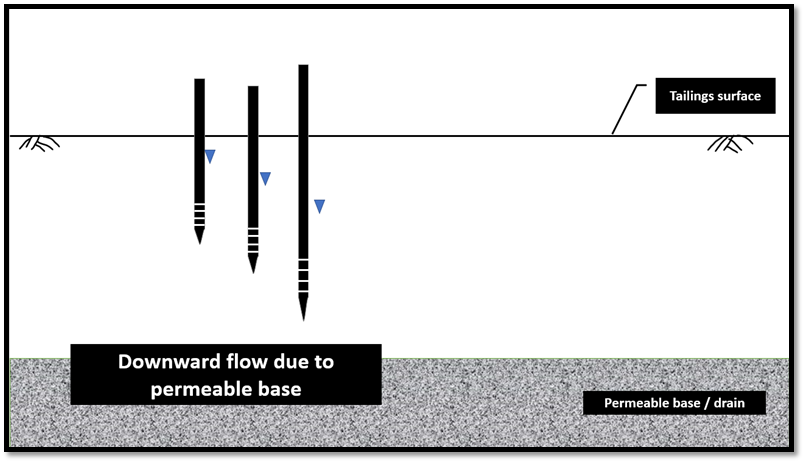

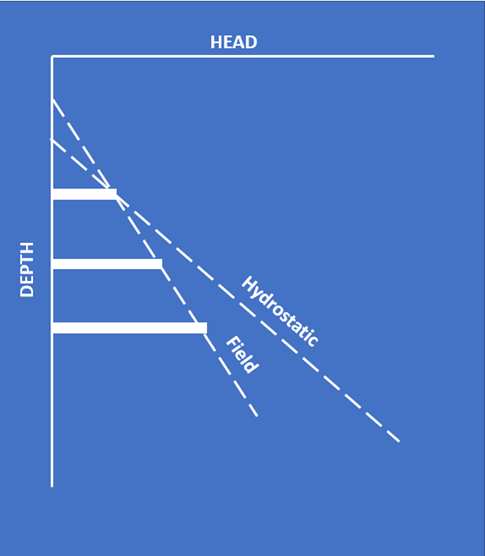

Once installed, my boss asked me to add some water to each, and then to come back the next day and measure the depth to the water in each of the piezometer tubes and keep measuring until the water level had stabilized. To my surprise, once stabilized, each piezometer had a different water elevation inside its tubing. My boss, who was a geotechnical engineer, had been monitoring the CPTu logs each day, and he knew from the pore pressure dissipation test results and based on the facility design (which included a full drainage blanket within the TSF footprint area) that the pore pressure regime would be lower than hydrostatic pressure due to a downward flow component from the seepage. This piezometer performance is illustrated in Figures 1 and 2. Those piezometers helped to establish the pore pressure model which was used in the slope stability analysis. And I learned a valuable lesson.

Notice that the real (field) depth to the phreatic surface is different than the phreatic surface implied by assuming a hydrostatic pore pressure distribution from the shallowest piezometer. This could have a very significant impact on the outcome of a slope stability analysis. The latter interpretation would be unconservative. What if I only had the middle piezometer? Or only the deepest piezometer? Where would I imagine the phreatic surface to be?

Kindly note that if I had installed only a single piezometer, the pore pressure regime would still be largely unknown, and only misleading information would have been available for use in the slope stability model.

At the second site, we had also just completed drilling, sampling and in situ testing (including CPTu probing). I still had a sizable amount of metal water pipe and a few isolated-tip drive-point piezometers with me. Because I was still a newly minted mining engineer at the time, I was still not appreciating the data that we were receiving from the CPTu tests. Again, I contacted my supervisor to get instructions on what to do with the piezometers and water pipe. He told me to do about the same thing as before: to have the drill rig press them into the tailings, each at a different depth, but all in close proximity to one-another. And then he said that we should add as much pipe above the tailings surface as we had available. Once we did that, the tops of the pipes were so high that I couldn’t get to them to measure the depth to water. My supervisor instructed me come observe the pipes the next day.

When I returned the following day there was water flowing from the top of each of the piezometer tubes. Again, my boss had been monitoring the CPTu logs each day, and he knew from the pore pressure dissipation test results and based on the facility design (which included a full geomembrane liner within the TSF footprint area and no drainage) that the pore pressure regime would be well above hydrostatic pressure. The rate of tailings deposition far exceeded the tailing’s ability to dissipate the high pore pressures. Those piezometers helped to demonstrate to the mine owner the challenges they would be facing, especially as closure, reclamation and cover placement approached. And I learned another very valuable lesson.

The primary lesson to be learned here is that a single piezometer does not provide sufficient information to understand the pore pressure regime. Piezometers need to be installed in arrays, and especially at more than one depth per location. Hydrostatic pore pressures are the exception, rather than the rule in tailings facilities.

Comments (2)

Nana Bonsu Osei

July 26, 2022 at 2:11 pmThank you. Got some clarity on things that were kind of in abstract to me.

admin

July 28, 2022 at 2:21 amWell, I’m very glad. Sometimes the simplest lessons are the best.

Comments are closed.